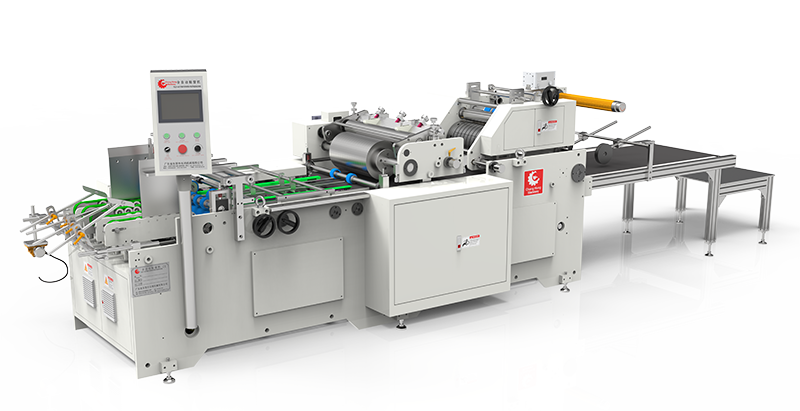

Automatic High Speed Flute Laminator, DS-1450/1700

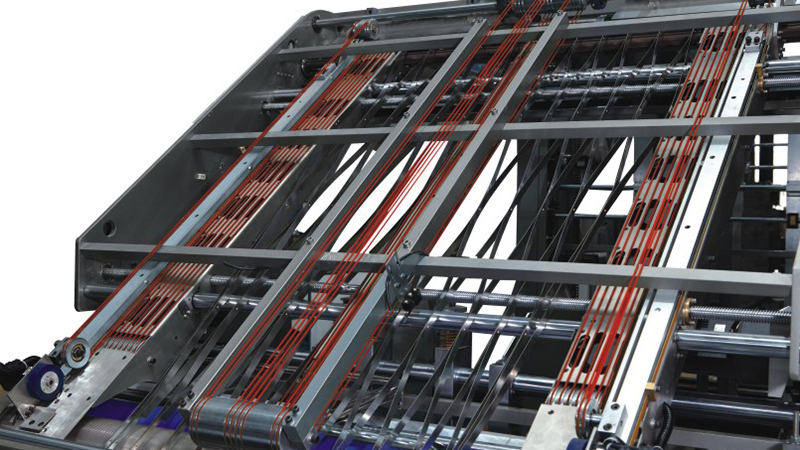

DINGSHUNG automatic high speed flute laminator is capable of performing all types of laminating jobs, such as laminating corrugated board with cardboard, cardboard with cardboard, cardboard with grey board.

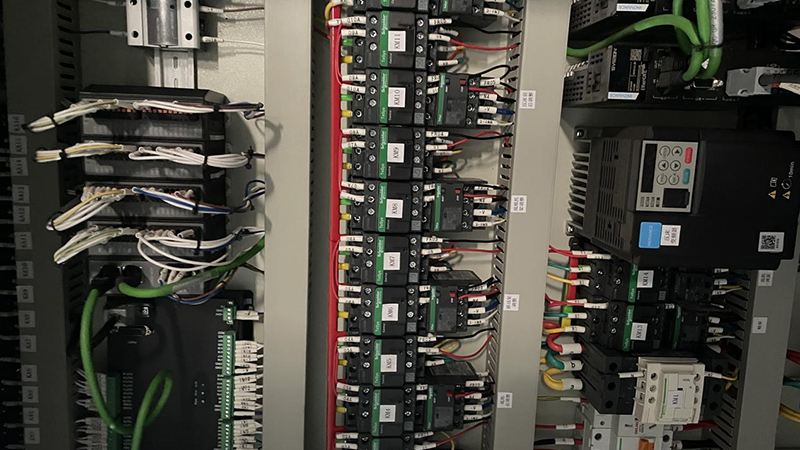

- Quick adjustment: one-click smart adjustment, using a motion control system, simply input the paper size and the system adjusts automatically.

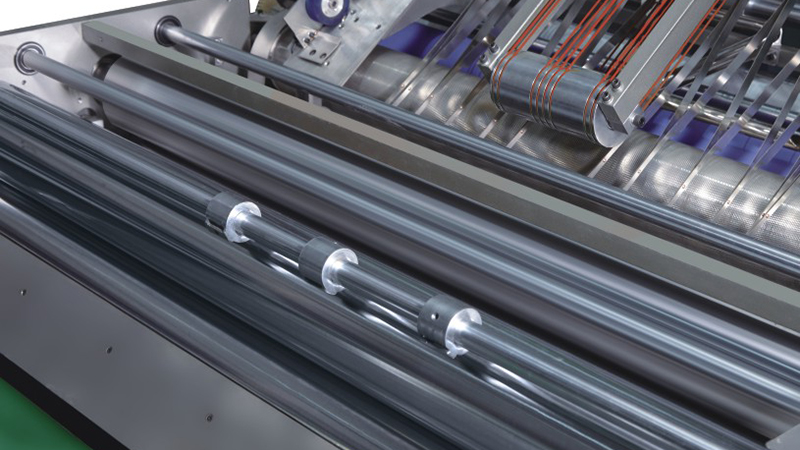

- High speed: the maximum laminating speed is 15,000 sheets per hour (180m/min).

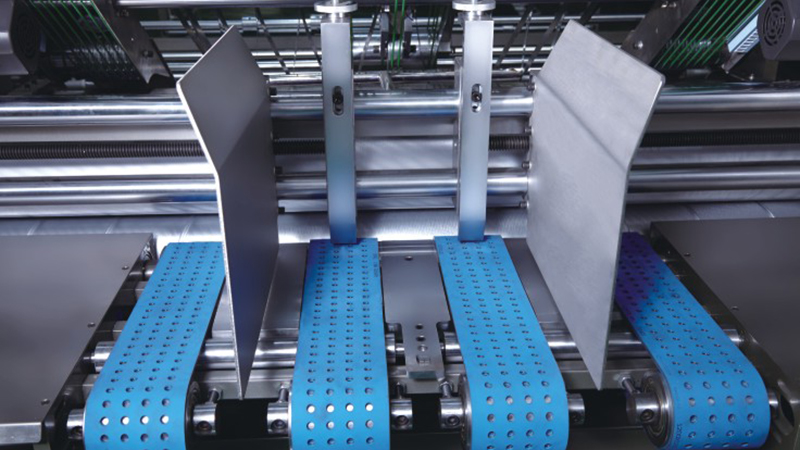

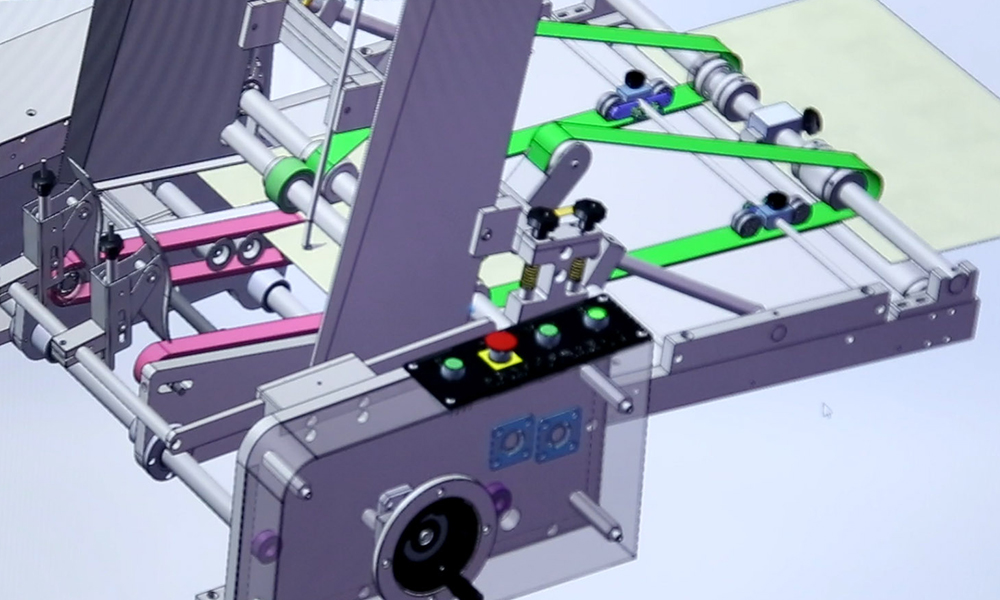

- High precision: high-speed motion control, front lay positioning and full-length tracking of the side lay ensure high-speed lamination accuracy of ±1mm.

- Can be used for both paperboard and corrugated board lamination.