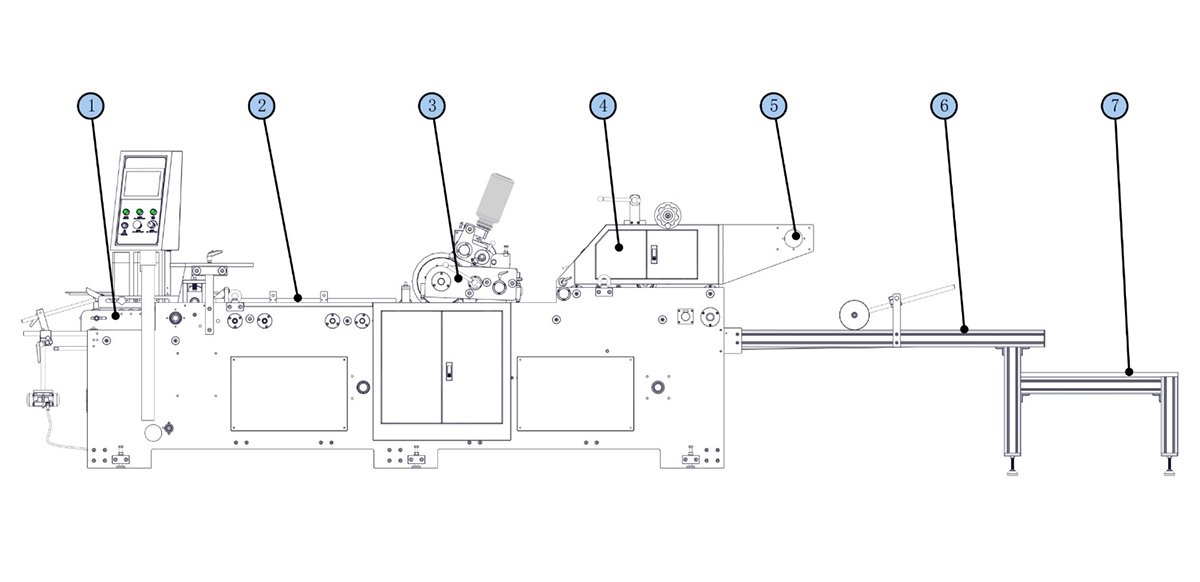

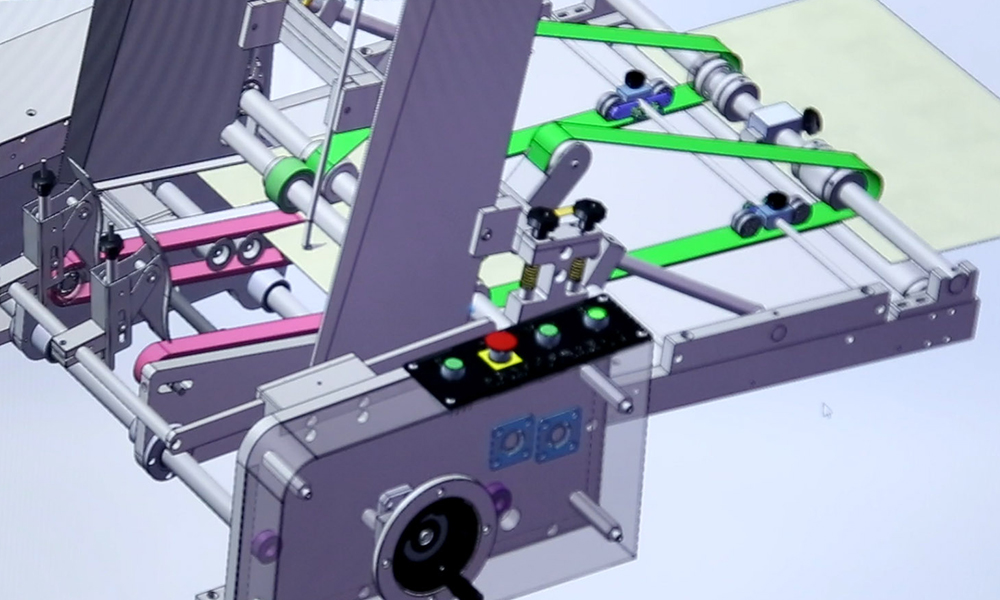

Single Lane Window Patcher, TC-650/1100

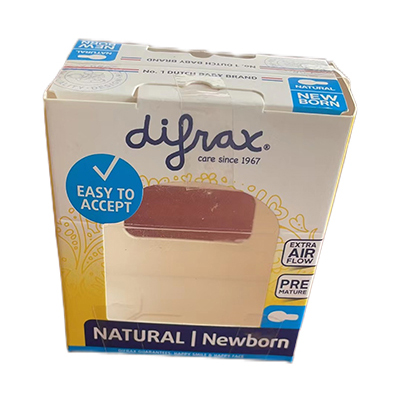

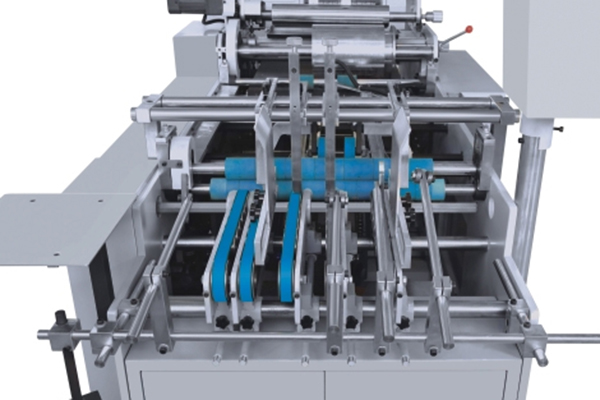

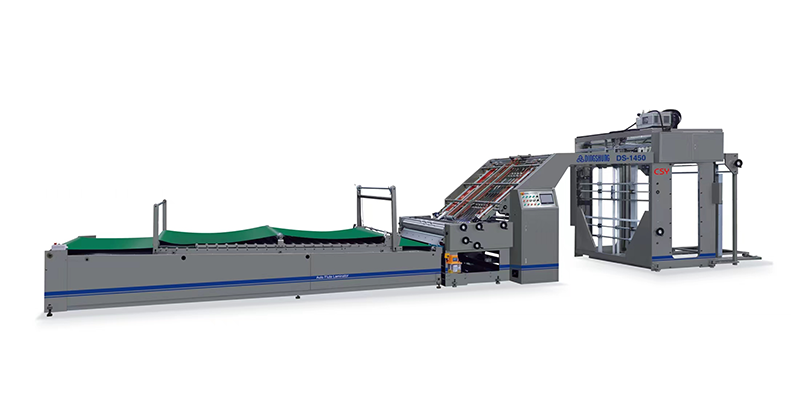

ChangHong single lane window patcher is a fully automatic high-speed window patching machine that runs single production line at a time, offering a maximum speed of 20,000 boxes per hour. The maximum window size is 380mm in width and the 500mm in length. This window applicator is ideal for window patching on tissue boxes, cosmetic boxes, gift boxes, handicraft boxes, and other paper boxes. It can also be used for partial film patching onto cardboard and corrugated cardboard. In addition, the carton windowing machine is equipped with a mono-suction belt, which ensures continuous feeding of carton blanks. TC-650/1100 single lane window patcher is an ideal choice for manufacturers in the carton box industry, providing efficient and reliable window patching capabilities.

Request a Quote