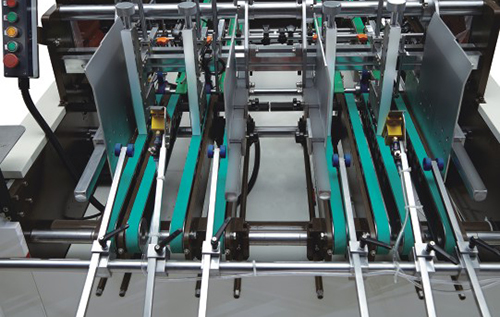

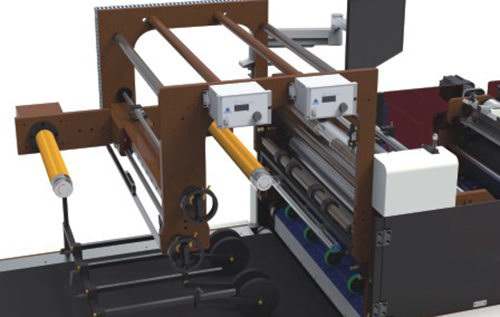

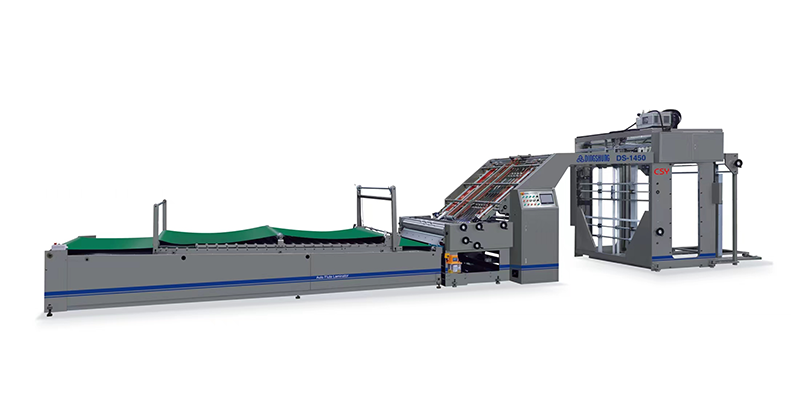

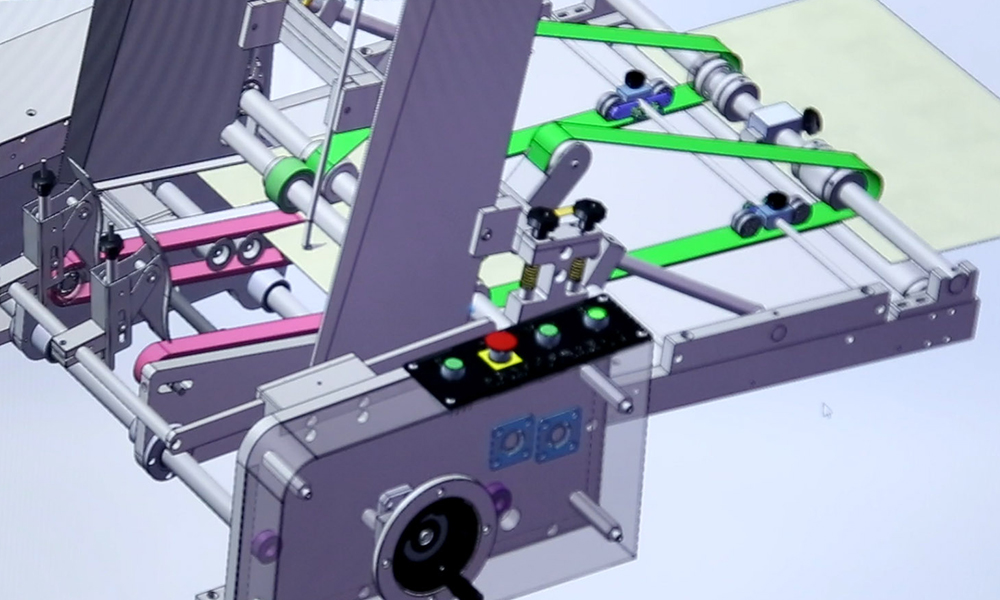

Servo Driven Dual Lane Window Patcher, TC-1100H

ChangHong servo driven dual lane window patcher is capable to run two production lines at a time, delivering a maximum production speed of 10,000 pcs/h. If the carton is too large, the operator can decide to use single-line production mode. Equipped with a PLC control system, the gluing and filming position can be adjusted by inputting the parameters on the touch screen without stopping the machine. Currently, this high speed window patcher has been widely used in the window patching process of tissue boxes, cosmetic boxes, gift boxes, and craft boxes, among other cardboard boxes.

Request a Quote